genauere Messungen in Böden mit hoher Leitfähigkeit

Überblick

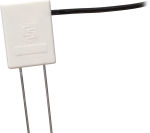

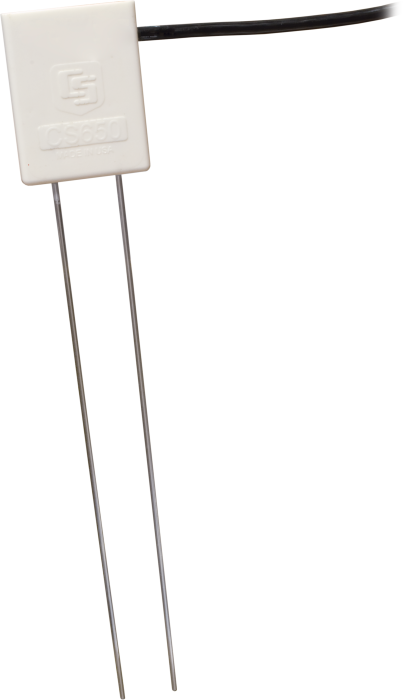

Der CS650 ist eine Multiparametersonde, die innovative Technik zur Bestimmung des volumetrischen Wassergehalts, der elektrischen Leitfähigkeit und der Temperatur nutzt. Er gibt ein SDI-12 Signal aus, das fast alle unsere Logger messen können.

Lesen Sie mehrFunktionen und Vorteile

- Genauere Messungen des Bodenwassergehalts mit elektrischer Leitfähigkeit bis zu 3 dS/m ohne eine bodenspezifische Kalibrierung durchzuführen

- Größeres Probenvolumen reduziert Fehler

- Messwerte werden korrigiert zur Vermeidung von Effekten durch verschiedene Bodenarten und elektrische Leitfähigkeiten

- Kalkuliert Badenwassergehalt für viele mineralische Böden

- Vielseitiger Sensor, misst elektrische Leitfähigkeit, volumetrischen Wassergehalt, Dielektrizitätskonstante und Temperatur

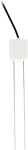

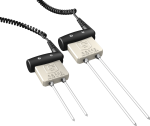

Bilder

Zugehörige Produkte

Technische Beschreibung

The CS650 consists of two 30-cm-long stainless steel rods connected to a printed circuit board. The circuit board is encapsulated in epoxy and a shielded cable is attached to the circuit board for datalogger connection.

The CS650 measures propagation time, signal attenuation, and temperature. Dielectric permittivity, volumetric water content, and bulk electrical conductivity are then derived from these raw values.

Measured signal attenuation is used to correct for the loss effect on reflection detection and thus propagation time measurement. This loss-effect correction allows accurate water content measurements in soils with bulk EC ≤3 dS m-1 without performing a soil specific calibration.

Soil bulk electrical conductivity is also calculated from the attenuation measurement. A thermistor in thermal contact with a probe rod near the epoxy surface measures temperature. Horizontal installation of the sensor provides accurate soil temperature measurement at the same depth as the water content. Temperature measurement in other orientations will be that of the region near the rod entrance into the epoxy body.

Kompatibel mit

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Datenlogger

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR300 (retired) | ||

| CR3000 | ||

| CR310 | ||

| CR350 | ||

| CR6 | ||

| CR800 (retired) | ||

| CR850 (retired) |

Additional Compatibility Information

RF Considerations

External RF Sources

External RF sources can affect the probe’s operation. Therefore, the probe should be located away from significant sources of RF such as ac power lines and motors.

Interprobe Interference

Multiple CS650 sensors can be installed within 4 inches of each other when using the standard datalogger SDI-12 “M” command. The SDI-12 “M” command allows only one probe to be enabled at a time.

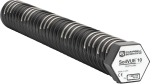

Installation Tool

The CS650G makes inserting soil-water sensors easier in dense or rocky soils. This tool can be hammered into the soil with force that might damage the sensor if the CS650G were not used. It makes pilot holes into which the rods of the sensors can then be inserted.

Spezifikationen

| Measurements Made | Soil electrical conductivity (EC), relative dielectric permittivity, volumetric water content (VWC), soil temperature |

| Required Equipment | Measurement system |

| Soil Suitability | Long rods with large sensing volume (> 6 L) are suitable for soils with low to moderate electrical conductivity. |

| Rods | Not replaceable |

| Sensors | Not interchangeable |

| Sensing Volume | 7800 cm3 (~7.5 cm radius around each probe rod and 4.5 cm beyond the end of the rods) |

| Electromagnetic |

CE compliant Meets EN61326 requirements for protection against electrostatic discharge and surge. |

| Operating Temperature Range | -50° to +70°C |

| Sensor Output | SDI-12; serial RS-232 |

| Warm-up Time | 3 s |

| Measurement Time | 3 ms to measure; 600 ms to complete SDI-12 command |

| Power Supply Requirements | 6 to 18 Vdc (Must be able to supply 45 mA @ 12 Vdc.) |

| Maximum Cable Length | 610 m (2000 ft) combined length for up to 25 sensors connected to the same data logger control port |

| Rod Spacing | 32 mm (1.3 in.) |

| Ingress Protection Rating | IP68 |

| Rod Diameter | 3.2 mm (0.13 in.) |

| Rod Length | 300 mm (11.8 in.) |

| Probe Head Dimensions | 85 x 63 x 18 mm (3.3 x 2.5 x 0.7 in.) |

| Cable Weight | 35 g per m (0.38 oz per ft) |

| Probe Weight | 280 g (9.9 oz) without cable |

Current Drain |

|

| Active (3 ms) |

|

| Quiescent | 135 µA typical (@ 12 Vdc) |

Electrical Conductivity |

|

| Range for Solution EC | 0 to 3 dS/m |

| Range for Bulk EC | 0 to 3 dS/m |

| Accuracy | ±(5% of reading + 0.05 dS/m) |

| Precision | 0.5% of BEC |

Relative Dielectric Permittivity |

|

| Range | 1 to 81 |

| Accuracy |

|

| Precision | < 0.02 |

Volumetric Water Content |

|

| Range | 0 to 100% (with M4 command) |

| Water Content Accuracy |

|

| Precision | < 0.05% |

Soil Temperature |

|

| Range | -50° to +70°C |

| Resolution | 0.001°C |

| Accuracy |

|

| Precision | ±0.02°C |

Dokumente

Broschüren Produkte

Technische Artikel

Realisierte Projekte

Übereinstimmung mit Richtlinien u. Vorschriften

FAQs für

Number of FAQs related to CS650: 50

Alle anzeigenWenige anzeigen

-

Damage to the CS650 or the CS655 electronics or rods cannot be repaired because these components are potted in epoxy. Cable damage, on the other hand, may possibly be repaired. For more information, refer to the Repair and Calibration page.

-

The CS650-series sensors have several logical tests built into their firmware to ensure that the sensors do not report a number that is known to be erroneous. Erroneous readings are either outside the sensor’s operational limits or outside of published accuracy specifications.

A reported value of NAN or 9999999 does not necessarily mean that there is a problem with the sensor hardware. The conditions outlined below can lead to a value of NAN or 9999999 for permittivity and volumetric water content.

SDI-12 communications issue

If all of the following are true, there is likely an issue with the SDI-12 communications between the sensor and the data logger: the sensor is being polled with an M1! SDI-12 command, the permittivity value reported is NAN, and subsequent values are all zeroes or never change. Possible causes include the following:

- The sensor is not powered. Check to make sure that the red wire is well connected to a 12 Vdc source and that the black wire is connected to data logger ground.

- The sensor signal wire is not connected properly. Ensure that the green wire is well connected to the control port specified in the data logger program.

- The sensor has an SDI-12 address that does not match the data logger program.

- The sensor has cable or lightning damage.

Calculated permittivity is less than 0 or greater than 88

The equation used to convert period average and electrical conductivity values to permittivity is a three-dimensional surface with two independent variables and eleven coefficients, plus an offset. Some rare combinations of period and electrical conductivity result in a permittivity calculation that is less than air (1) or greater than water at 0°C (88). These rare combinations are not expected when the sensor is in soil.

Bulk electrical conductivity (EC) is greater than 1.14 dS/m

When bulk electrical conductivity is greater than 1.14 dS/m, the solution EC is greater than 3 dS/m, which is the upper limit for accurate readings with the CS650. When this occurs, the soil is considered out-of-bounds and will report a value of NAN or 9999999 for both permittivity and volumetric water content.

Calculated permittivity is less than 80% of the permittivity limit

A permittivity limit based on the bulk electrical conductivity (EC) reading is used to determine whether the bulk EC at saturation exceeds the sensor’s operational limit. That permittivity limit is calculated and compared to the permittivity reading. If the measured permittivity is more than 20% beyond the permittivity limit, both permittivity and volumetric water content are reported as NAN or 9999999. This is the most common cause of NAN values with the CS650-series sensors, and it occurs because of the soil properties and not because of a sensor malfunction.

-

Campbell Scientific does not recommend using the CS650 or the CS655 to measure water content in compost. A compost pile is a very hostile environment for making dielectric measurements with soil water content sensors. All of the following combine to make it very difficult to determine a calibration function: high temperature, high and varying electrical conductivity, high organic matter content, heterogeneity of the material in the pile, changing particle size, and changing bulk density. The temperature and electrical conductivity values reported by the CS650 or CS655 may give some useful information about processes occurring in the compost pile, but these sensors will not be able to give useful readings for water content.

-

The electrical conductivity (EC) of sea water is approximately 48 dS/m. The CS650 can measure permittivity in water with EC between 0 and 3 dS/m. EC readings become extremely unstable at conductivities higher than 3 dS/m and are reported as NAN or 9999999. Because EC is part of the permittivity equation, an EC reading of NAN leads to a permittivity reading of NAN as well. Thus, the CS650 cannot provide good readings in sea water.

With regard to sea ice, the electrical conductivity drops significantly when sea water freezes and the permittivity changes from approximately 88 down to approximately 4, as the water changes from a liquid to a solid state. With both EC and permittivity falling to levels that are within the CS650 measurement range, the sensor is expected to give valid readings in sea ice. The sensor is rugged and can withstand the cold temperatures. However, as the ice melts, there will be a point at which the electrical conductivity becomes too high to acquire a valid reading for either permittivity or electrical conductivity.

-

If information is available on soil texture, organic matter content, and electrical conductivity (EC) from soil surveys or lab testing of the soil, it should be possible to tell if the soil conditions fall outside the range of operation of the sensor. Without this information, an educated guess can be made based on soil texture, climate, and management:

- Soil that is coarse textured (such as sand, loamy sand, or sandy loam) works well with a CS650 if the EC is low.

- If the soil is located in an arid or semiarid region, it may have high EC.

- If the soil is frequently fertilized or irrigated with water that has higher EC, it may have high EC.

- If the climate provides enough rain to flush accumulated salts below the root zone, the EC is expected to be low and suitable for a CS650.

When in doubt about soil texture and electrical conductivity, Campbell Scientific recommends using a CS655 because of the sensor’s wider range of operation in electrically conductive soils, as compared with the CS650.

-

No. The equation used to determine volumetric water content in the firmware for the CS650 and the CS655 is the Topp et al. (1980) equation, which works for a wide range of mineral soils but not for organic soils. In organic soils, the standard equations in the firmware will overestimate water content.

When using a CS650 or a CS655 in organic soil, it is best to perform a soil-specific calibration. For details on performing a soil-specific calibration, refer to “The Water Content Reflectometer Method for Measuring Volumetric Water Content” section in the CS650/CS655 manual. A linear or quadratic equation that relates period average to volumetric water content will work well.

-

No. It is not possible to disable the logical tests in the firmware. If soil conditions cause frequent NAN values, it may be possible to perform a soil-specific calibration that will provide good results.

If permittivity is reported but the volumetric water content value is NAN, Campbell Scientific recommends a soil-specific calibration that converts permittivity to water content. This will take advantage of the bulk electrical conductivity correction that occurs in the firmware.

If both permittivity and volumetric water content have NAN values, it may be possible to perform a calibration that converts period average directly to volumetric water content.

For details on performing a soil-specific calibration, refer to “The Water Content Reflectometer Method for Measuring Volumetric Water Content” section in the CS650/CS655 manual. After a soil-specific equation is determined, it may be programmed into the data logger program or used in a spreadsheet to calculate the soil water content.

-

The CS650 has rods that are 30 cm long, and the CS655 has rods that are 12 cm long. The difference in rod length causes some changes in specifications. For example, the CS650 is slightly more accurate in its permittivity and water content readings, but the CS655 works over a larger range of electrical conductivity. In addition, the CS650 handles a larger measurement volume and provides good accuracy in low EC (electrical conductivity) sand and sandy loam. The CS655 is typically more accurate in soil, works well over a wide range of soil textures and EC, and is easier to install because of its shorter rods.

-

A CS650 or CS655 can be ordered with an SDI-12 address option of -VS. With the -VS option, the SDI-12 address is set at the factory before the sensor is shipped. The last digit of the sensor’s serial number becomes that sensor’s SDI-12 address. Typically, the -VS option is chosen when there are multiple sensors that will communicate with the data logger on the same SDI-12 communications terminal.

If the -VS option is not selected when ordering, the CS650 or CS655 will ship with its SDI-12 address set to 0 (the default -DS option). The address can be changed to a non-zero value using the A200 Sensor to PC Interface or by connecting the sensor to an SDI-12 communications terminal and sending the aAb! Command as described in the “SDI-12 Sensor Support” appendix of the CS650/CS655 manual.

-

If a system has multiple CS650 or CS655 sensors, it will be necessary to connect many wires to a 12 V supply and many wires to ground. The DIN Rail Mounting Kit is useful for attaching many wires to the same source in a clean and organized way. For more details, see the 5458 DIN Rail Terminal Kit instruction manual.

Other methods of connecting several wires together, such as terminal strips or wire nuts, would also work.